EMPEL™ delivers Premium Performance, Distinct Comfort, and the ability to create New Products.

Direct Consumer Benefits

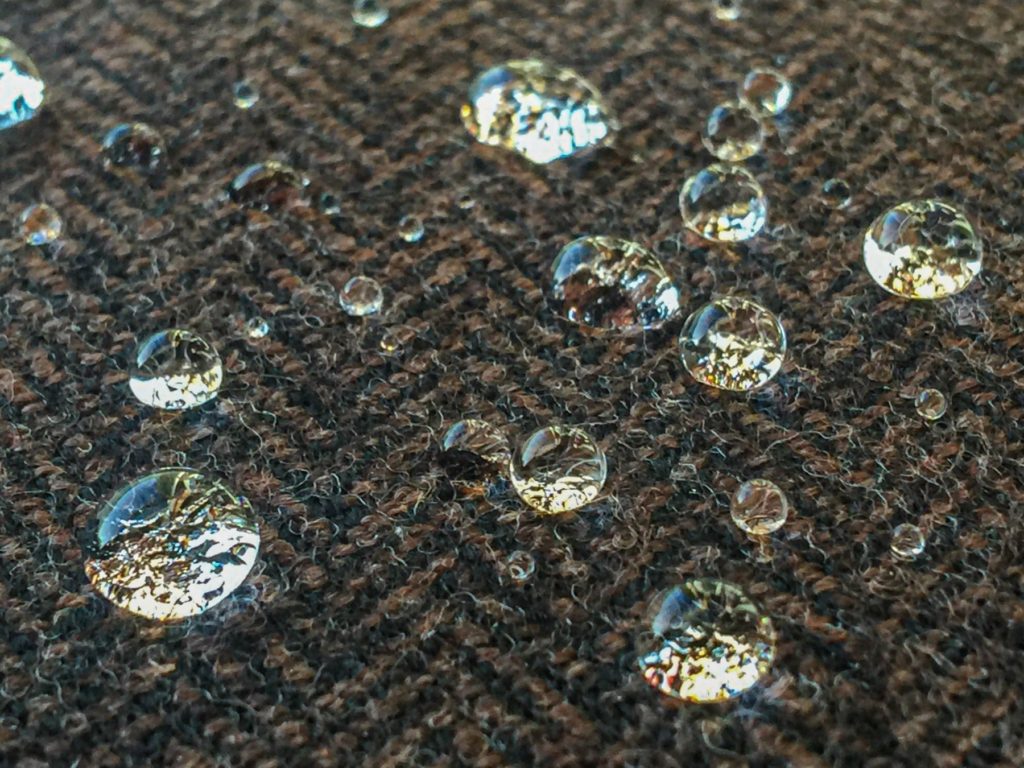

- 10x Premium Water Protection – In head to head severe rain testing, EMPEL Molecular Water Protection performs 10x better than the leading water repellent treatments. We endure the extremes of 6 hour Hurricane rain chamber tests to make sure EMPEL won’t fail you in a hard rain.

- Enhanced Breathability – Breathable fabrics are more comfortable to wear. We don’t coat fabrics with stiff chemistries or plastics. Our microscopic process is uniformly bonded to each fiber to enhance the natural breathability of the fabric. Air can freely pass between the yarns and still keep out larger water molecules.

Superior Performance

There are several reasons why EMPEL™ delivers superior protection and performance results:

- Covalent molecular bonding causes EMPEL™ monomers to lock together in long polymer chains. These long chains add to the hyper water repellent function of EMPEL™ Molecular Water Protection. The polymer bonding also locks to the fibers of the fabric at the same time for better long-term durability.

New product concepts powered by EMPEL

- FINALLY, luxury fabrics like wools and silk can be built with performance functions without changing the soft hand feel or appearance. Treated wool blazers and peacoats can be worn directly into the rain and keep people dry for hours. In internal tests at GTT, our fine wool fabrics pass the Bundesmann test for 20-30 minutes, 2-3 times the standard test limits.

An innovation platform with the same base chemistry, process and machinery

- The EMPEL™ innovation platform includes clean chemistry, a dry finishing process that uses no water and new patented lower cost machinery.

- This same chemistry can be used to bond many different performance functions to fabrics. Several functions can be applied at the same time in the same batch. The resulting fabric attributes are revolutionary and unique.